greybeard

Herd Master

We call that flywheel torque, as the formula is strictly for engine or motor output.

Torque is the measure in foot-pounds (ft.-lbs.) of the amount of work an engine can perform. Horsepower is the measure of how quickly that work can be done

It's the transmission gearing and final drive gearing that enables a tractor to be a tractor..

You aren't taking into consideration the transmission+final drive gearing, and, the size of the wheel/tire assy has to also be considered as part of the gearing.

You will have to know the gear ratios for each gear, as well as the ring and pinion size in the final drive and the wheel/tire diameter to accurately calculate torque.

It's why drawbar torque and PTO torque are different from each other and both are different from engine torque. The gearing multiplies engine torque.

We tend to think of torque in relation to what we have always thought of and referenced in automobiles, but they do it completely different/opposite. Automobile eng designers start with torque and develop HP from it, while tractor designers start with hp and develop torque from that.

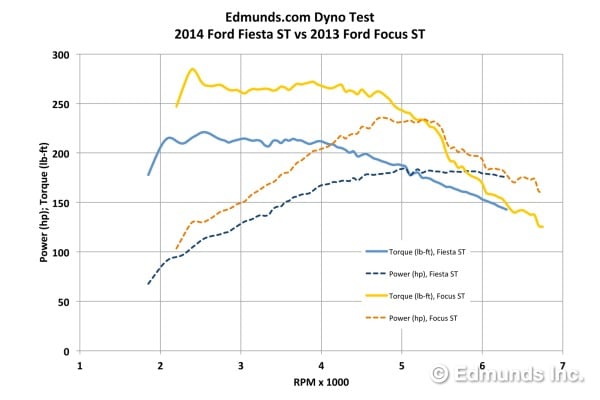

as one person put it.here's an interesting bit of trivia:

below 5252 rpm any engine's torque number will always be higher than its horsepower number, and above 5252 rpm any engine's horsepower number will always be higher than its torque number. At 5252 rpm the horsepower and torque numbers will be exactly the same.

Again, flywheel torque, not torque at the wheels.

examples...

Torque is the measure in foot-pounds (ft.-lbs.) of the amount of work an engine can perform. Horsepower is the measure of how quickly that work can be done

It's the transmission gearing and final drive gearing that enables a tractor to be a tractor..

You aren't taking into consideration the transmission+final drive gearing, and, the size of the wheel/tire assy has to also be considered as part of the gearing.

You will have to know the gear ratios for each gear, as well as the ring and pinion size in the final drive and the wheel/tire diameter to accurately calculate torque.

It's why drawbar torque and PTO torque are different from each other and both are different from engine torque. The gearing multiplies engine torque.

We tend to think of torque in relation to what we have always thought of and referenced in automobiles, but they do it completely different/opposite. Automobile eng designers start with torque and develop HP from it, while tractor designers start with hp and develop torque from that.

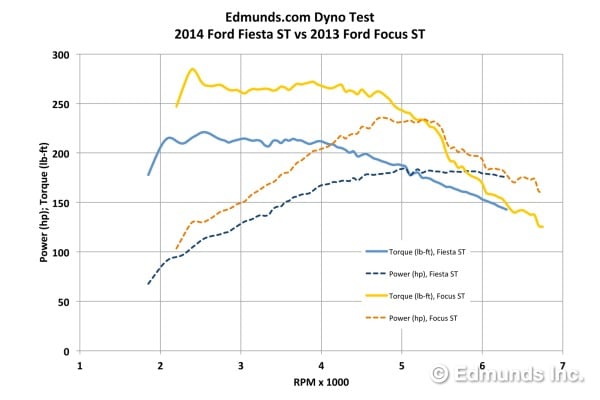

as one person put it.here's an interesting bit of trivia:

below 5252 rpm any engine's torque number will always be higher than its horsepower number, and above 5252 rpm any engine's horsepower number will always be higher than its torque number. At 5252 rpm the horsepower and torque numbers will be exactly the same.

Again, flywheel torque, not torque at the wheels.

examples...

.....I know ya will sure have fun and enjoy figuring out all the amazing things ya can use it for....hopefully, it'll even come in handy for some of the snow removal too. My Dad has used cinder blocks or bricks to mark the tire spots for his attachments.....when the tires hit them he was where he needed to be to attach whatever to it.....it may just work for you too.....

.....I know ya will sure have fun and enjoy figuring out all the amazing things ya can use it for....hopefully, it'll even come in handy for some of the snow removal too. My Dad has used cinder blocks or bricks to mark the tire spots for his attachments.....when the tires hit them he was where he needed to be to attach whatever to it.....it may just work for you too.....